Our creations find application in the sectors of fashion, workwear, leather goods, furniture, household linen and footwear, but also for more technical sectors such as automotive and medical, with the possibility of customized creations both in quantitative terms and type of processing. Different possibilities of bias cutting, tape bending, tape stitching, creation of piping, pleating are available, to make each product original. Over the years we have expanded the range of our processes, offering to our clients a punctual and all-round service, thanks to the 300 square meters warehouse with a complete range of finished and semi-finished products. This way we are able to find original solution to each client’s request.

We carry out different fabric cutting techniques: heat sealing, knife cutting or rotating-blade cutting. We can carry out these processes both on synthetic or natural fabrics and, on request, on specific client’s material.

The bias folding process solves many application problems for clothing manufacturers, but not only. The bias fabric acquires “elasticity” allowing the bias tape to adapt better to any type of fabric during the manufacturing phase. We can carry out the classic 45°skew, but also other inclinations are available to give greater or less elasticity to the various types of materials.

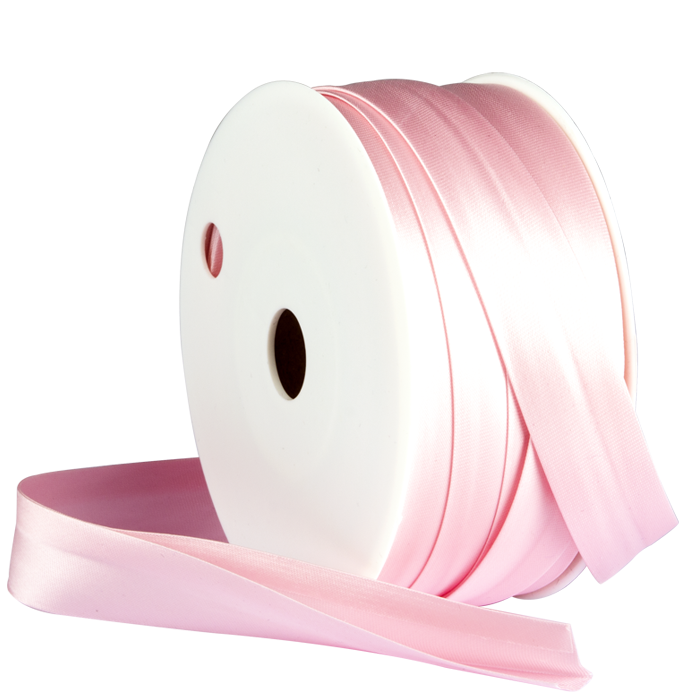

Thanks to our great experience, we are able to produce folded tapes of different types and sizes. From the classic symmetrical fold on both sides, to book fold, quadruple fold, multiple fold and asymmetrical fold. We pay great attention to customer’s requests and are very flexible in providing solutions to the problems posed by customers.

Chain stitching, lock or linear stitching, zigzag stitching, embroidery and overlock. A wide range of processes and sewing, to create new and customized items every day for an exclusive aesthetic and accurate workmanship with attention to the details.

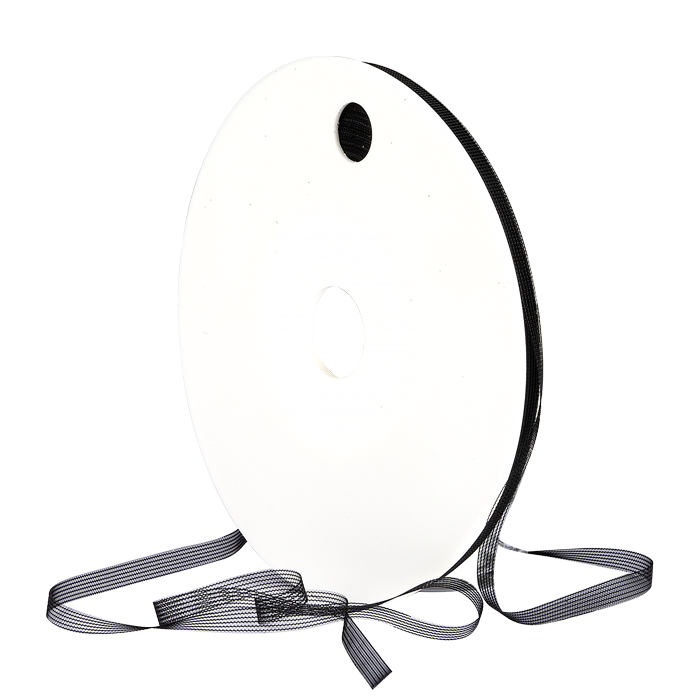

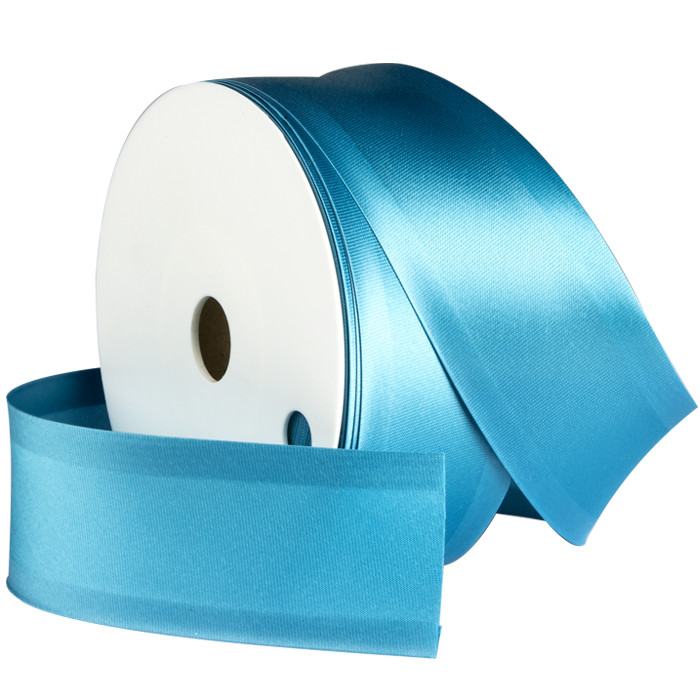

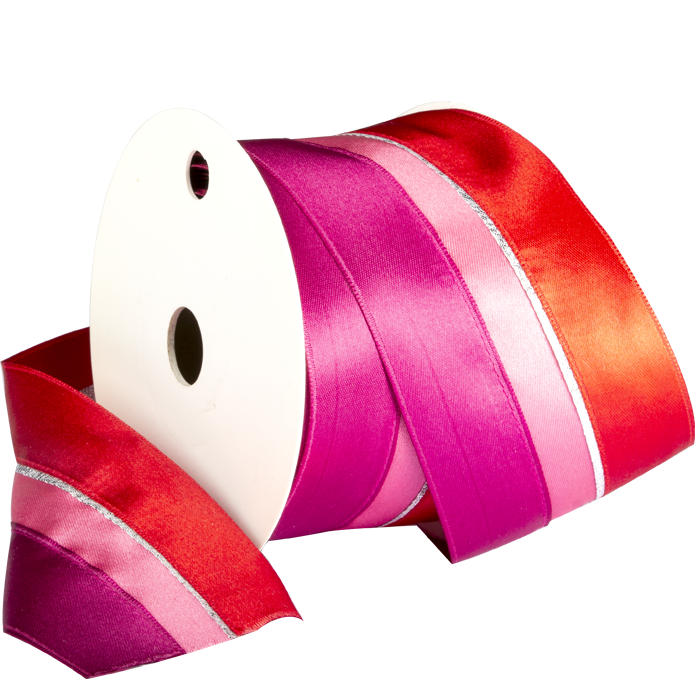

Ribbon production with needle or crochet looms, in a large variety of items and with the possibility to customize each product to meet specific customer's request.

We create piping in single or multiple colors, with customizable dimensions both for the finished height of the tape and for the size of the round. We can carry out these processes both on bias fabrics and on elastic fabrics.

We assemble the ribbons through seams, cuts and folds to create customized belts, edges and trimmings. We find industrializable solutions for stylists’ most ambitious projects and most innovative applications.

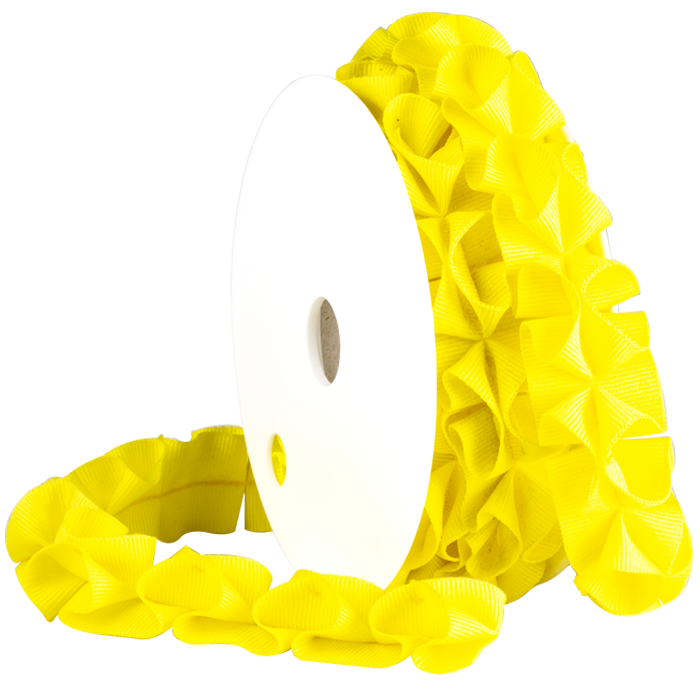

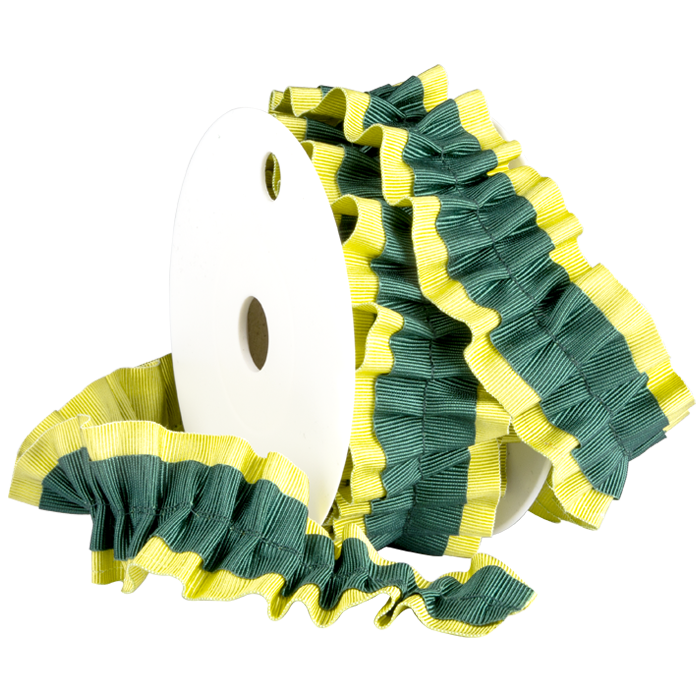

Searching for new textile shapes in fashion has led us to functional and original solutions. Among the ribbon pleating techniques we find simple, multi-needle, multi-fold or elastic pleating. Our experience in this field allows us to carry out different processes each time using each type of material.

Achievable on fabrics with a good percentage of synthetic composition, the high-frequency processing on tape allows us to engrave the material creating designs with a clean cut and sealing the threads of the fabric.

Laser cutting on continuous tape allows to cut tapes in a precise and clean way. This means we can create 100% customized design, and we make precise cuts with edges without traces of burns or fading.

Thanks to the sublimation transfer printing we are able to customize ribbons with subjects of any type, printed on polyester or other synthetic fiber ribbons, with the guarantee of always bright colors.